Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Automatic Single Auger Filler Powder Packing Machine

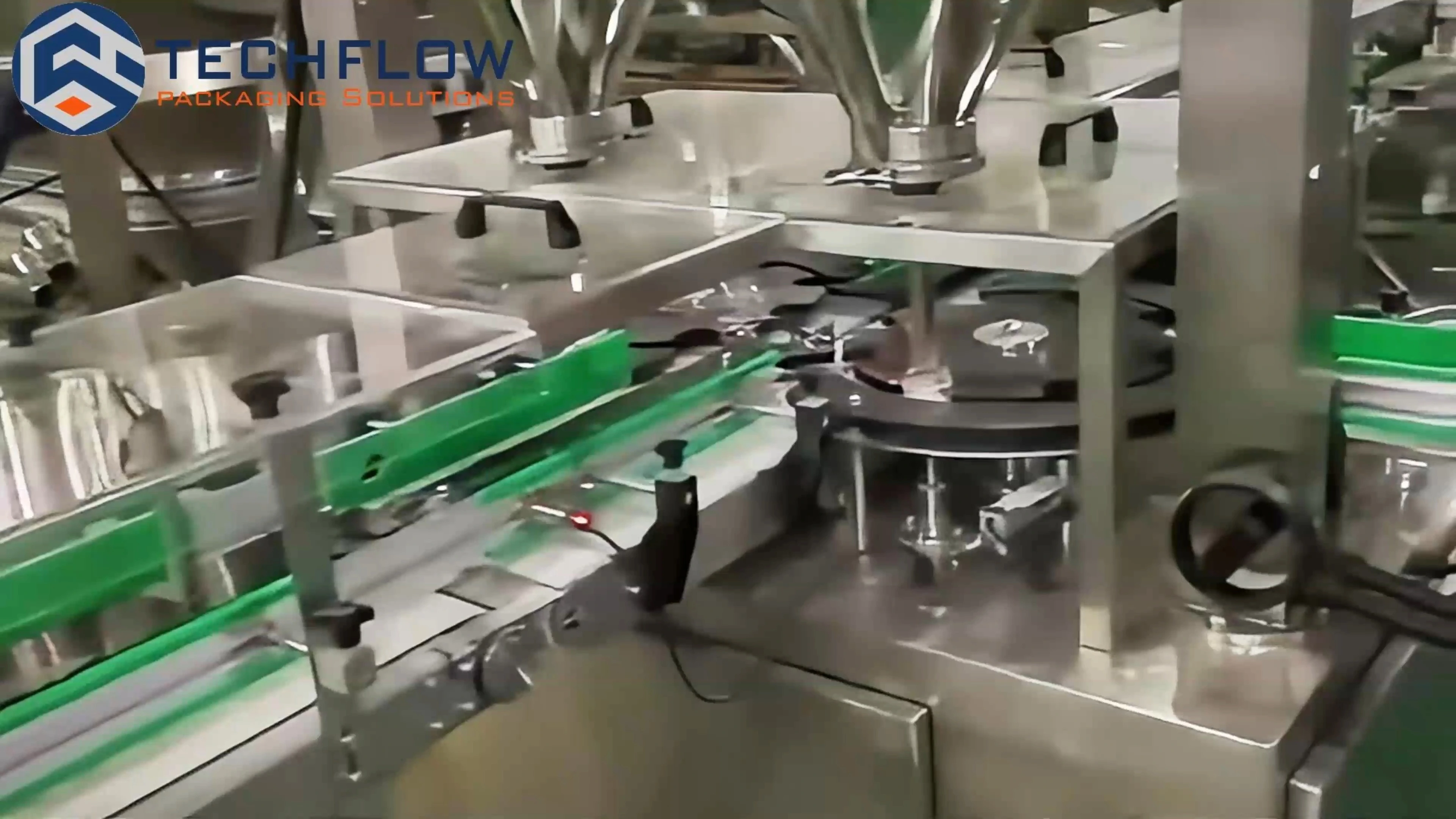

Automatic Single Auger Filler Powder Packing Machine is our new standard type packing equipment for powdery material or fine granules cans/bottles auto packing. This machine is composed of auger filler, S.S304 outside structure, Chain conveyor, Cans seamer&capper etc.

Machine Model: TFP-2A

Main functions: Auger filling and cans seaming

Filling range: Max500g

Indicative price: $9,000-22,000

Applications: Cans/Jars/bottles

Configuration: SIEMENS+SEW+SCHNEIDER

Product Description

Automatic Single Auger Filler Powder Packing Machine is our new standard type packing equipment for powdery material or fine granules cans/bottles auto packing. This machine is composed of auger filler, S.S304 outside structure, Chain conveyor, Cans seamer&capper etc.

Applications

This automatic powder packing machine is our new developed economical powder metering machine in the powder dosing and powder packaging industry, which can be applied to the quantitative measurement of a variety of powders or fine particles such as flour, coffee powder, milk powder, tapioca flour, seasoning powder, chemical powder and other materials. It is suitable for bags, cans,bottles semi-auto filling.

Technical Features 01

The whole machine is all stainless steel, and the frame and material contact part are 304 stainless steel. Excellent workmanship.

Technical Features 02

Designed to be steplessly adjustable at any time in the package, the working state can be changed at any time, and the operation is convenient.

Technical Features 03

The auger filling head column is lifted and lowered to adapt to different height bottles.

Technical Features 04

Touch screen man-machine interface: stable work, anti-interference, high weighing accuracy, touch screen man-machine interface is convenient and intuitive.

Technical Parameters

|

Machine Model |

TFP-2A |

|

Metering method |

Screw quantitative |

|

Filling range |

Max500g |

|

Filling accuracy |

<0.3%-1% |

|

Packing speed |

Max70 pcs/min(according to dosing weight and material's flowing ability) |

|

Hopper volume |

25L |

|

Power supply |

380/220V 50-60Hz, 1.2Kw |

|

Machine weight |

400kg |

|

Air source |

0.5-0.7Mpa |

|

Cans applicable size |

D:50-180mm; H: 50-350mm |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

SIEMENS |

|

2 |

HMI |

SIEMENS |

|

3 |

Photo sensor |

SICK |

|

4 |

Main motor |

SEW |

|

5 |

Electronic parts |

Schneider |

|

6 |

Servo motor |

INOVANCE/SIEMENS |

|

7 |

Pneumatic parts |

SMC/AIRTAC |

No.99#Shenmei Road, Pudong District, Shanghai,China