Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

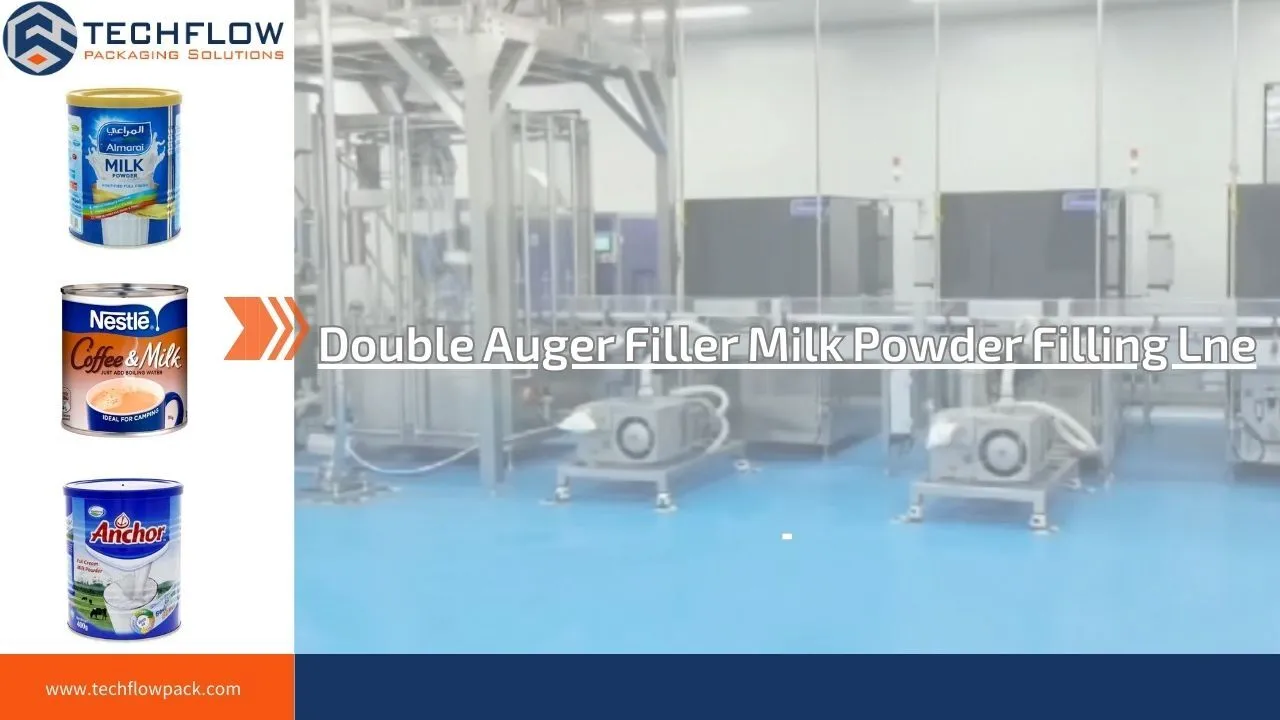

Automatic Double Auger Filler Milk Powder Filling Line

Automatic Double Auger Filler Milk Powder Filling Line is the end of powder packing line for Canned products. This milk powder filling line is composed of powdery or fine granular material conveying&handling system, auger fillers, Cans seamer&capper, Metal detector, Data printer etc.

Machine Model: TFP-2B3

Main functions: Auger filling and cans seaming

Filling range: Max5000ml

Indicative price: $90,0000-170,000

Applications: Cans/Jars

Configuration: SIEMENS+SEW+SCHNEIDER

Milk Powder Filling Line

Product Description

Automatic Double Auger Filler Milk Powder Filling Line is the end of powder packing line for Canned products. This milk powder filling line is composed of powdery or fine granular material conveying&handling system, auger fillers, Cans seamer&capper, Metal detector, Data printer etc. The blended milk powder enters the double-head milk powder filling machine through screw conveyor or vacuum conveyor to realize automatic measuring and feeding, and then complete the function of automatic sealing, capping and coding.

Product Specifications

Techflowpack is committed to helping customers deliver and build cost-effective milk powder filling lines

| Machine model | TFP-2B3 |

| Metering method | Screw quantitative |

| Filling range | Max5000ml |

| Filling accuracy | <0.3%-1% |

| Packaging Speed | Max50 pcs/min(according to dosing weight and material's flowing ability) |

| Hopper volume | 50L+16L |

| Power supply | 220V/380V, 50-60Hz |

| Machine weight | 3500kg |

| Air Source | 0.5-0.7Mpa |

| Cans application size | D:50-180; H:50-350mm |

| Total power of the line | 20Kw around |

| Main frame | S.S304 |

Product Application

Automatic Double Auger Filler Milk Powder Filling Line is mainly for Coffee powder, milk powder, Protein powder industries end of line packaging.This filling line is designed and constructed by TECHFLOWPACK. Client contacts with one window only from the contract signature, normal production and after service. It's mostly used for milk powder, protein powder canning(bottling) production.

PRODUCT STRENGTH

Products Advantages

Techflowpack's milk powder filling lines are known for their high filling accuracy and wide range of applications. Whether it is whole milk powder, baby milk powder, goat milk powder or camel milk powder, it can realize high precision filling from 200-2000 grams and control the precision within one thousandth.

WHY CHOOSE US?

Product Characteristics

Normally, our technicians will visit the customer's site to take measurements and give an optimal layout of the production line according to the safety standards of the dairy industry. Techflowpack's milk powder filling line has the following features

Working Flow

Cans unscrambler→Cans sterilization →Powders vacuum feeding→powder horizontal conveying (control the level of powder metering machine)→powder filling →electronic scale→injection Nitrogen unit →Cans seaming&capping →Cans cleaning→code printing

Product Details

Techflowpack's Dual Auger Milk Powder Filling Line

| PLC | INOVANCE/SIEMENS |

| HMI | INOVANCE/SIEMENS |

| Photo sensor | SICK |

| Main motor | SEW |

| Electronic parts | Schneider |

| Servo motor | INOVANCE/SIEMENS |

| Pneumatic parts | SMC/AIRTAC |

| Invetor | Danfoss |

Related Cases display

Tell

No.99#Shenmei Road, Pudong District, Shanghai,China