Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

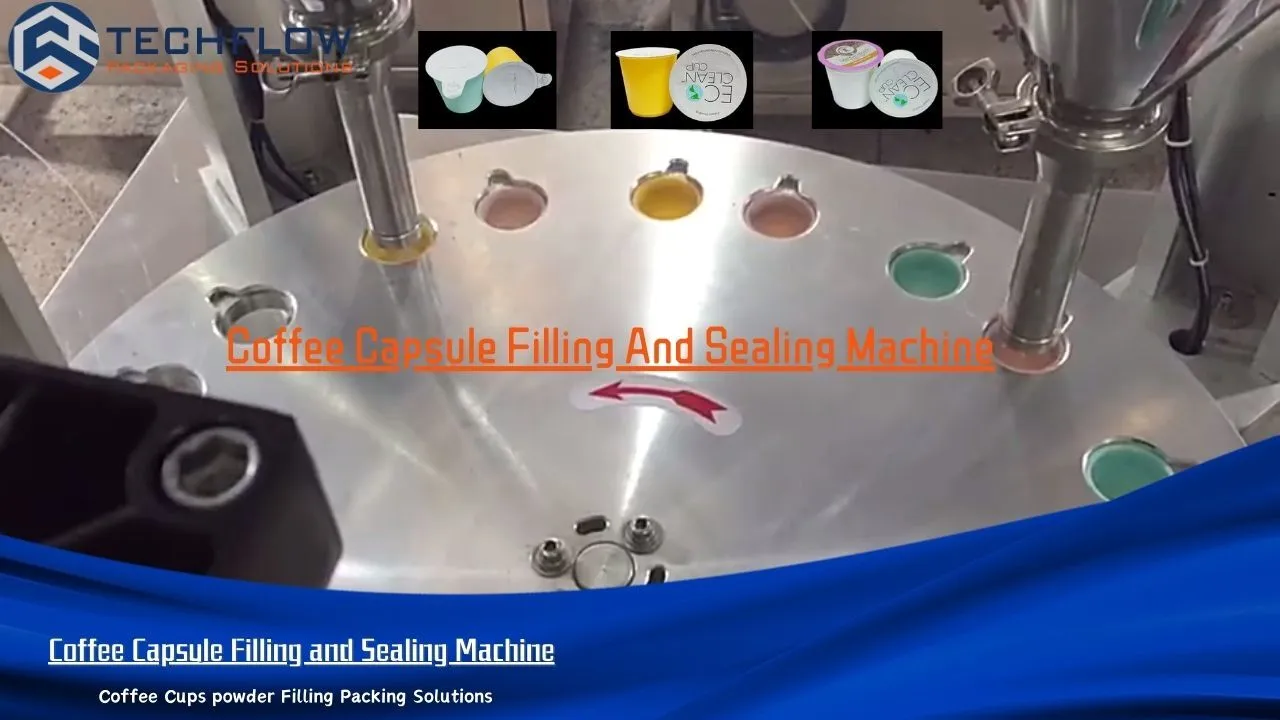

Fully automatic coffee capsule powder filling and sealing machine

The fully automatic coffee capsule powder filling and sealing machine is designed to efficiently and precisely fill and seal coffee capsules. Its advanced technology enables it to achieve high-speed production and consistent product quality. Its selling points include its ability to accurately measure and fill coffee powder, its superior sealing capabilities, and its user-friendly operation, making it an ideal choice for coffee manufacturers looking to streamline their production process and deliver top-quality coffee to consumers.

Machine Model: TFP-CCF2

Main functions: Coffee Cups Auger filling and sealing

Production capacity: Max1200 cups/hour

Indicative price: $7,000-10,000

Applications: Premade coffee cups/coffee capsules

Configuration: OMRON+GPG+SCHNEIDER

product description

The fully automatic coffee capsule powder filling and sealing machine efficiently fills coffee capsules with the desired amount of powder and seals them, ensuring a convenient and mess-free brewing experience. This automated process saves time and guarantees consistent quality for a perfect cup of coffee every time.

The fully automatic coffee capsule powder filling and sealing machine offers a convenient and efficient solution for filling and sealing coffee capsules. With its automated functions, it ensures consistent and precise filling, reducing manual labor and increasing productivity.

Applications

The fully automatic coffee capsule powder filling and sealing machine is a state-of-the-art device designed to efficiently fill and seal coffee capsules using powdered ingredients. This advanced machine streamlines the process, ensuring precise and consistent filling while maintaining the freshness and quality of the coffee.

Technical Features 01

It adopts aluminum acid-resistant mold, which is hygienic and safe, and has a long service life. The coffee cup or capsule automatically falls into the mold.

Technical Features 02

Equipped with high-precision sensors and photoelectricity, cups or boxes can be automatically positioned and filled without manual control of the switch. No cup or filling required.

Technical Features 03

After the filling is completed, the machine automatically puts the sealing film after sensing the cup. If there is no cup, the sealing film will not be placed, saving material waste.

Technical Features 04

After the film is released, it is automatically sealed and the cup is automatically dispensed. According to customer needs, coding or inkjet coding functions can also be added to realize automatic identification of product production information.

Technical Parameters

|

Machine Model |

TFP-CCF2 |

|

application type |

Preformed cups/capsules |

|

Filling heads |

2 auger fillers |

|

Production capacity |

Max 1200pcs/min |

|

Gas consumption |

100NL/min |

|

Gas pressure |

0.6-0.8mpa |

|

Power supply |

220/110V;1.5Kw |

|

Machine dimension |

1000x1000x16500mm |

|

Machine weight |

300Kg |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

OMRON |

|

2 |

HMI |

Weiview |

|

3 |

Photo sensor |

SICK |

|

4 |

Main Drive |

GPG |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

Airtac/SMC |

|

7 |

Main structure |

Stainless steel and Aviation aluminum |

No.99#Shenmei Road, Pudong District, Shanghai,China