Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

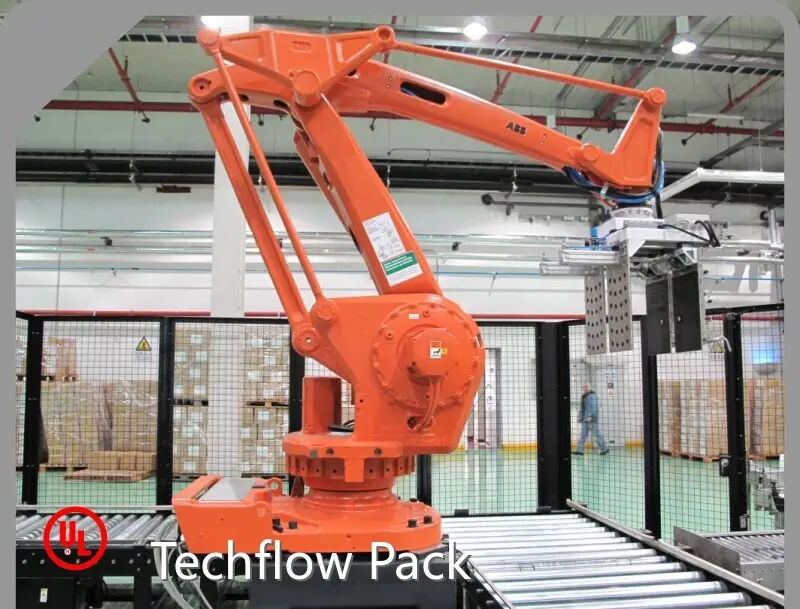

Robotic Palletisers Company Techflow Pack

Product details of the robotic palletisers

Quick Detail

With a focus on product quality, Techflow Pack manufactures robotic palletisers strictly according to national and industry standards. The eco-friendly and energy-saving product is of fine workmanship, good exterior, good safety, and reliable quality. All this makes it more cost-effective than other products in the same category. Our Techflow Pack robotic palletisers is made to meet the highest quality standards. The performance and quality of the product is stable and reliable. robotic palletisers is used for fermentation of all kinds of bread. It is widely applied to places including bakeries, hotels, restaurants, and others. 上海利湃机械设备有限公司 has perfect product testing facilities and capable technology team.

Product Information

Our robotic palletisers is more competitive than similar products, as shown in the following aspects.

Product Description

Robot Palletizer is the product of the organic combination of machinery and computer program. It provides higher production efficiency for modern production. Robot palletizers have a wide range of applications in the palletizing industry. The palletizing robot greatly saves labor and space. The palletizing robot operates flexibly, accurately, quickly and efficiently, with high stability and high efficiency.

Applications

The palletizing robot can be integrated in any production line to provide intelligence, robotization and networking for the production site, and can realize palletizing logistics for a variety of operations in the beer, beverage and food industries, and is widely used in cartons, plastic boxes, bottles, bags, barrels, film package products and filling products. It is equipped with a three-in-one filling line, etc., and palletizes all kinds of bottles, cans, bags and bags. The automatic operation of the palletizer is divided into automatic box feeding, box transfer, arrangement, stacking, pile moving, stacking, feeding, stacking, stacking, and stacking.

Work flow

Before robot palletizer system working, forklift places 10 empty pallets on the pallet dispenser; the pallet dispenser will send the empty pallet to the stacking position, products comes to the accelerate belt conveyor which will expand the distance between each product through the speed difference; the steering system will turn the direction of product according to the arrangements; the arrangement buffer system will arrange the products in order; the robot will grab the complete layer of product and place it on the pallet in order, repeat the actions, until finishing palletizing the complete pallet, then the roller conveyor will transport the complete pallet to the position for forklift.

Accelerating belt line → Steering mechanism → Arrangement and buffer system → Robot → Gripping platform → Lifting platform → Finish ← Roller conveyor ← Pallet supply system

Technical Features 01

Box-steering mechanism: when the box steers, the speed of the bottom conveyor line is the same with that of the rear part of accelerating belt line; when the box needs to be rotated 90°, the cylinder will stretch out quickly to block the one side of the box.

Technical Features 02

Gripper head : the main frame material is aluminum alloy and SUS304.

Technical Features 03

Arrangement and buffer system: boxes are transferred to this system through the roller conveyor. In order to better meet customers' requirements for arrangement, an adjustable stop bar is installed under the system, which can be freely adjusted by hand and provide various modes of arrangement, thereby increasing the efficiency.

Technical Features 04

Roller conveyor line: its main frame is the varnished carbon steel. It consists of heavy-load roller conveyor line, which is used to convey empty pallets and full stack of products to workstation of the forklift.

Technical Parameters

|

Model |

TFP-RP400 |

|

Packaging Capacity |

Max 12cycles / min |

|

Power supply |

380V 50-60Hz 3P |

|

Power |

20Kw |

|

Maximum load per layer |

150Kg |

|

Maximum load per pallet |

1500kg |

|

Working Gas Source |

0.5-0.7MPa |

|

Air Consumption |

150NL/Min |

|

Weight |

2000kg |

|

Main frame |

Carbon steel with printing |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

Driving motor motor |

SEW |

|

2 |

PLC |

Siemens |

|

3 |

HMI |

Siemens |

|

4 |

Photo Sensor |

SICK |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

SMC/FESTO |

|

7 |

Inverter |

Danfoss |

Company Advantages

上海利湃机械设备有限公司 is a comprehensive company in the industry, and our main product is Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line. Based on the market demand, our company constantly pursues scientific innovation. Our goal is to provide consumers with all kinds of high-quality and safe products, and promote the sustainable development within the industry. Techflow Pack has an elite team with high cohesiveness and technical skills, which provides favorable conditions for the development. Based on customers' specific situations and needs, Techflow Pack provides comprehensive and reasonable solutions.

Techflow Pack's Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line are produced and sold directly from the factory. They have reliable quality and reasonable price. Bulk purchase is available. If needed, please contact us!

No.99#Shenmei Road, Pudong District, Shanghai,China