Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

High-qualitycan Depalletizer Machine

Product details of the can depalletizer machine

Quick Detail

Techflow Pack's machinery is made based on advanced production technology. They are self-adaptation, maintenance-free, and self-testing. They are of simple operation and great practicability. 上海利湃机械设备有限公司 employs can depalletizer machine material, which is up to the national standard. The product has features of excellent performance reliable operation. 上海利湃机械设备有限公司 promotes the systematic improvement of its competitiveness.

Product Description

Techflow Pack's can depalletizer machine is of excellent quality, which is reflected in the details.

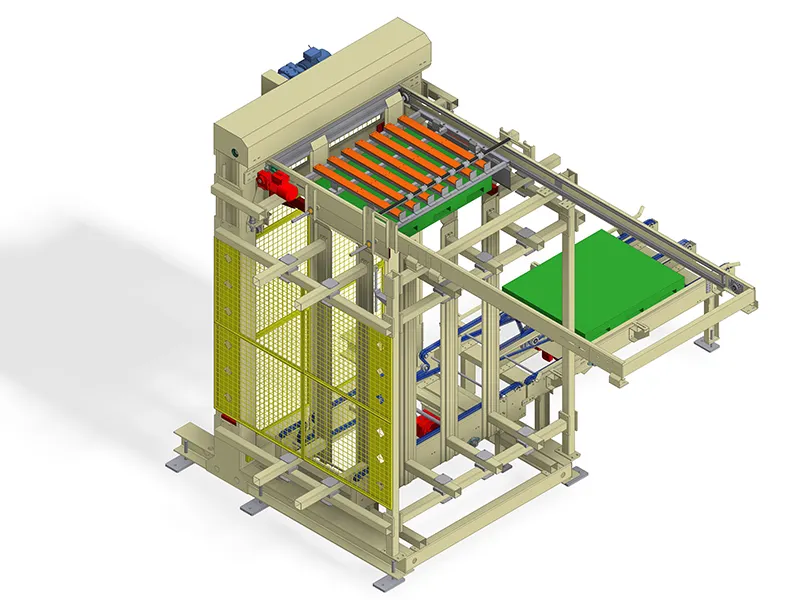

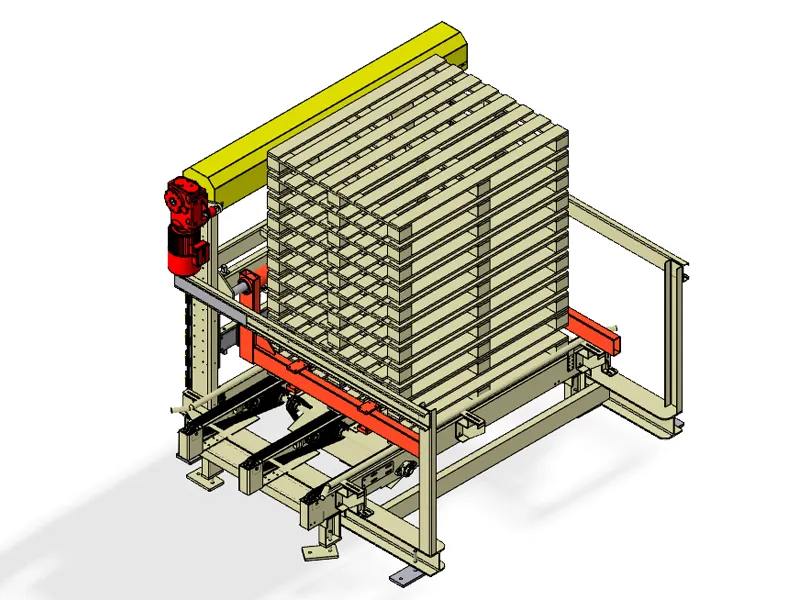

High level Depalletizer Machine

Product Description

Forklift transport the complete stack of empty bottles to the full pallet conveyor of High-level depalletizer, then the conveyor transport the full stack to the main lifting platform, the lifting platform lift up the full stack layer by layer.The interlayer collecting structure suck the interlayer and move it out of the stack, after that, the interlayer collecting mechanism will collect the interlayers and lift it down to conveyor when the interlayers is stored as one stack; the clamp of bottle grips the whole layer of bottles and moves them to empty bottle conveyors, repeat these actions until the all the layers are moved to the conveyor, then the lifting platform will down and output the empty pallet to the pallet magazine.

Product Specifications

Techflowpack is committed to helping customers to build cost-effective automatic high-level depalletizing system

| Machine model | TFP-HDP400 |

| Production capacity | 60,000pcs/hour |

| Container applications | PET&Glass Bottles/Cans/Jars |

| Machine weight | 3500kg |

| Air Source | 0.8Mpa |

| application size | D:50-180; H:50-250mm(customized) |

| Power supply | 380V, 50-60Hz, 16Kw around |

| Main frame | Carbon steel with painting |

Product Application

The high level depalletizer is mainly used in the high-speed packaging production line of liquid, beverage, food, daily chemical and other industries for the separation of the whole stack of empty glass bottles and metal cans, the removal of partitions and pallets, and the realization of orderly conveyance of empty bottles and cans to the front part of the production line and automatic infeeding.

PRODUCT STRENGTH

Products Advantages

Techflowpack's High Level Depalletizer or Depalletizing sytems are known for their high production capacity and wide range of applications. Whether it is beer botttling line, beverage filling line, cans filling line or Jar filling line, it can realize high speed depalletizing with stack pallets and partitions removal sucessful.

WHY CHOOSE US?

Product Characteristics

Normally, our technicians will visit the customer's site to take measurements and give an optimal layout of the production line according to the safety standards of the food industry. Techflowpack's high-level depalletizer machine has the following features

Product Details

Techflowpack's High-level depalletizer

| PLC | SIEMENS |

| HMI | SIEMENS |

| Photo sensor | SICK |

| Motor with brake | SEW+OMT |

| Electronic parts | Schneider |

| Servo motor | INOVANCE/SIEMENS |

| Pneumatic parts | SMC/FESTO |

| Invetor | Danfoss |

Related Cases display

Tell

Company Introduction

Techflow Pack is widely accepted by its customers from all over the world mainly for its can depalletizer machine. The production process of can depalletizer machine is advanced. Techflow Pack strives to be a leading can depalletizer machine manufacturer. Contact us!

Techflow Pack's Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line are produced and sold directly from the factory. They have reliable quality and reasonable price. Bulk purchase is available. If needed, please contact us!

No.99#Shenmei Road, Pudong District, Shanghai,China