Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Automatic Side Loading Wrap Around Case Packer for Tetrapack Boxes and Gaptop boxes

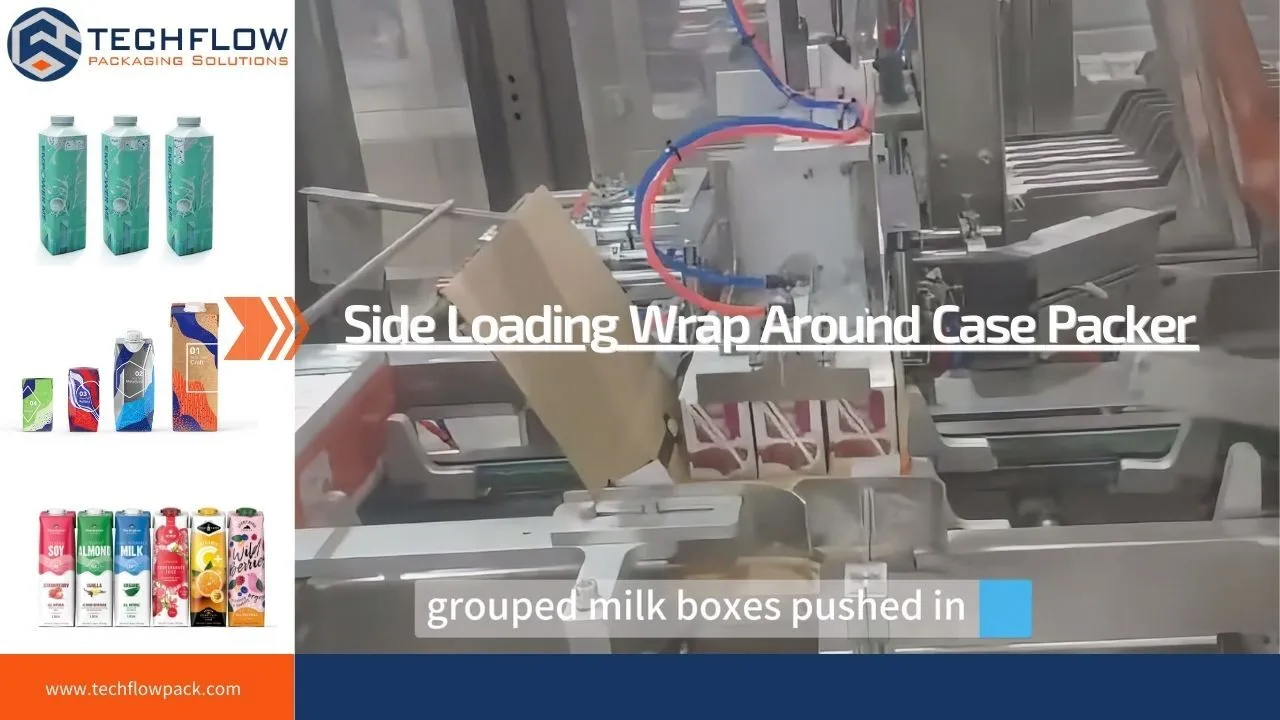

Side Loading Wrap around Case Packer, also called Side Pushing Wraparound Carton Packaging Machine, is a compact way for small boxes and cans wrap around case packaging. It's mainly used for beverage, Dairy Industries. This machine integrates boxes auto feeding, wrap around carton blanks auto forming, glue spraying and carton sealing in one then greatly reduce the production cost and workshop floor space. The product enters the machine via the servo divider infeed conveyor as a given group to the case packing unit, where the product is automatically pushed into the positioned wraparound blank then forming and glue sealing.

Machine Model: TFP-WSL18

Packing format: 2x3,3x4,4x6

Boxes sizes: 200,500,1000ml etc

Machine capacity: Max18 cartons/min

Indicative price: $60,000-80,000

Applications: Bottles/Cans/Boxes

Configuration: SIEMENS+NORDSON+SCHNEIDER

Product Description

Side Loading Wrap around Case Packer, also called Side Pushing Wraparound Carton Packaging Machine, is a compact way for small boxes and cans wrap around case packaging. It's mainly used for beverage, Dairy Industries. This machine integrates boxes auto feeding, wrap around carton blanks auto forming, glue spraying and carton sealing in one then greatly reduce the production cost and workshop floor space. The product enters the machine via the servo divider infeed conveyor as a given group to the case packing unit, where the product is automatically pushed into the positioned wraparound blank then forming and glue sealing.

Applications

Side Loading Wrap Around Case Packer is mainly for small boxes, especially for milk boxes(Tetrapack and Gaptop) automatic carton packing with hot melt glue sealing. By adjusting the dividing mechanism and the carton forming mechanism, it is possible to run several products of different specifications on the same machine.

Technical Features 01

Straight product conveying line: used for conveying with inverted bottle testing mechanism, full bottle detection mechanism, missing package detection mechanism, bottle pressure mechanism, and pressure relief mechanism. It is used to group product conveying and arranging.

Technical Features 02

Main drive uses of servo motor as the main drive, a series of cylinder action folding, with side spray glue and side pressure mechanism, the box moved to each station, and for a process, the final sealing box output.Adopt PLC to control the complete system of the machine,Man-machine interface screen control.

Technical Features 03

Cardboard storage mechanism for storing and placing cardboard, cardboard storage area using cylinder with one-way bearing to achieve cardboard propulsion, according to the size of the product carton, the mechanism can be adjusted up and down left and right, with less paper alarm, no paper stop, non-stop paper and other function.

Technical Features 04

Safety Door and Security systems used to prevent safety accidents caused by the accidental intrusion of personnel during the automatic movement of the ground rail machine. Ensure the safety of personnel;The hardware circuit of the machine's emergency stop switch is connected, and the safety door is opened under abnormal circumstances, and the machine is stopped immediately to avoid any accidents and losses.

Technical Parameters

|

Machine Model |

TFP-WSL18 |

|

Carton application type |

wrap around carton/Paper tray |

|

Packing format |

2x3;3x4;4x6 |

|

Production capacity |

Max 18cases/min |

|

Gas consumption |

150NL/min |

|

Gas pressure |

0.4-0.7mpa |

|

Power supply |

380V 50-60Hz, 10Kw |

|

Machine dimension |

7900x2300x1850mm |

|

Machine weight |

2100Kg |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

SIEMENS |

|

2 |

HMI |

SIEMENS |

|

3 |

Photo sensor |

SICK |

|

4 |

Main Drive |

SEW/GPG |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

SMC/FESTO |

|

7 |

Servo motor/Servo drive |

INOVANCE/SIEMENS |

|

8 |

Hot melt glue applicator |

Nordson |

|

9 |

Main structure |

Carbon steel with painting+S.S304 |

No.99#Shenmei Road, Pudong District, Shanghai,China