Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

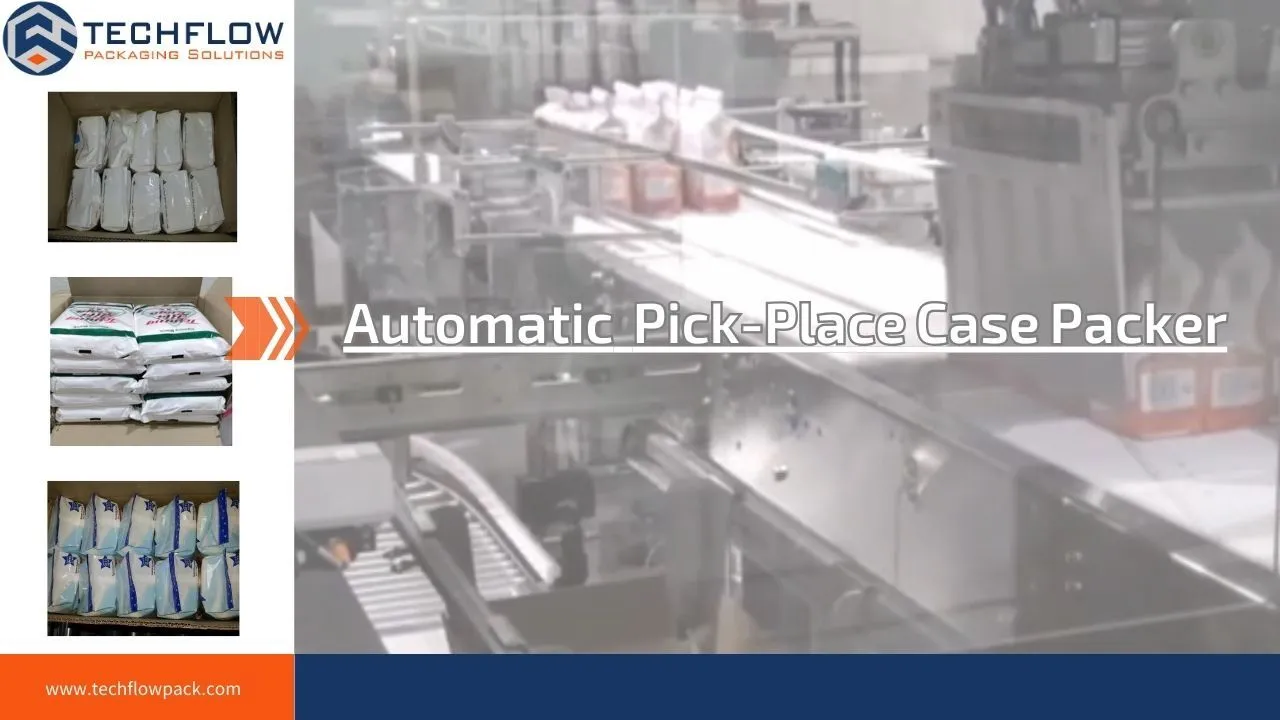

Fully automatic multi-function Pick-and-Place case packer

Fully automatic multi-function Pick-and-Place case packer also called Top-Load Case Packer, is the latest portable carton packaging machine developed by our technical team according to the mechanical principle of two-axis robotic arm.

Machine Model: TFP-PC25

Packing format: 2x2;2x3,2x4;3x4,4x6(customized)

Machine capacity: Max25 cartons/min

Indicative price: $19,000-32,000

Applications: Bottles/Bags/Cans/Jars/Boxes

Configuration: INOVANCE+SEW+SCHNEIDER

Product Description

The front-end servo splitting machine will divide the products transported by a single conveyor line into multiple channels, the full-material detection mechanism on the multi-channel mesh belt line detects the full material and gives the full material signal, the back-end pressure relief mechanism acts, so that the product pulls out the predetermined number of boxes of the product on the mesh belt line, and the robot receives the pressure relief and the predetermined number of boxes. The product is in place after grabbing and placing the product into the carton then complete carton sealing.

Applications

This multi-function Pick-and-Place case packer is a smart solution for high capacity continuous production especially the Heavy-duty product such as Jar(0.5L-2L) and bags(0.5-5kg). With strong structure and stable grapping action, this case packer has being used for Food, Beverage, Dairy, Daily Chemical Industries.It's mainly applicabale for bagged products, such as Premade standing pouches& Doypack bags, also boxed or bottled products auto carton top-laod packaging.

Technical Features 01

Two-axis Robot Arm’s main frame are made of aluminum profile and carbon fiber. Upside down installed on the machine's outside frame.Max loading: 60kg. Working space diameter: 1000mm, repeatability positioning: 0.02mm. The fixture adjusts according to the shape of the product.All protective door are equipped with safety switch. The machine will stop immediately when open the door, to ensure safe operation without accidents.

Technical Features 02

Main drive use of servo motor as the main drive, a series of cylinder action folding, with side spray glue and side pressure mechanism, the box moved to each station, and for a process, the final sealing box output.Servo drive control for carton loading to get products smoothly place in the carton.

Technical Features 03

Carton formed holder is made of SUS304 and aluminum alloy, which is synchronized by two cylinders as the power of up and down lifting, and the gear rack is used to achieve synchronization with the coupling.Flexible to handle different product by changeover the clamper&fixtures.

Technical Features 04

Carton loading conveyor is made of 3mm304 stainless steel, powered by the motor, conveyed by modular mesh belt, and the two sides are limited by the guardrail, and there is a blocking mechanism in the middle, and the blocking function is realized through the cylinder action. Manually adjust the position of the blocking cylinder and the position of the conveyor guardrail to realize the production of switching carton specifications.

Technical Parameters

|

Machine Model |

TFP-PC25 |

|

Carton application type |

RSC/American Carton |

|

Packing format |

2x3;3x4;4x6(customized) |

|

Production capacity |

Max 25cases/min |

|

Gas consumption |

150NL/min |

|

Gas pressure |

0.4-0.7mpa |

|

Power supply |

380V 50-60Hz, 4Kw |

|

Machine dimension |

2000x1500x2050mm |

|

Machine weight |

1400Kg |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

INOVANCE |

|

2 |

HMI |

INOVANCE |

|

3 |

Photo sensor |

SICK |

|

4 |

Main Drive |

SEW |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

Airtac/FESTO |

|

7 |

Servo motor/Servo drive |

INOVANCE |

|

8 |

Main structure |

Carbon steel with painting |

No.99#Shenmei Road, Pudong District, Shanghai,China