Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Techflow Pack Powder Pouch Packing Machine Manufacturers

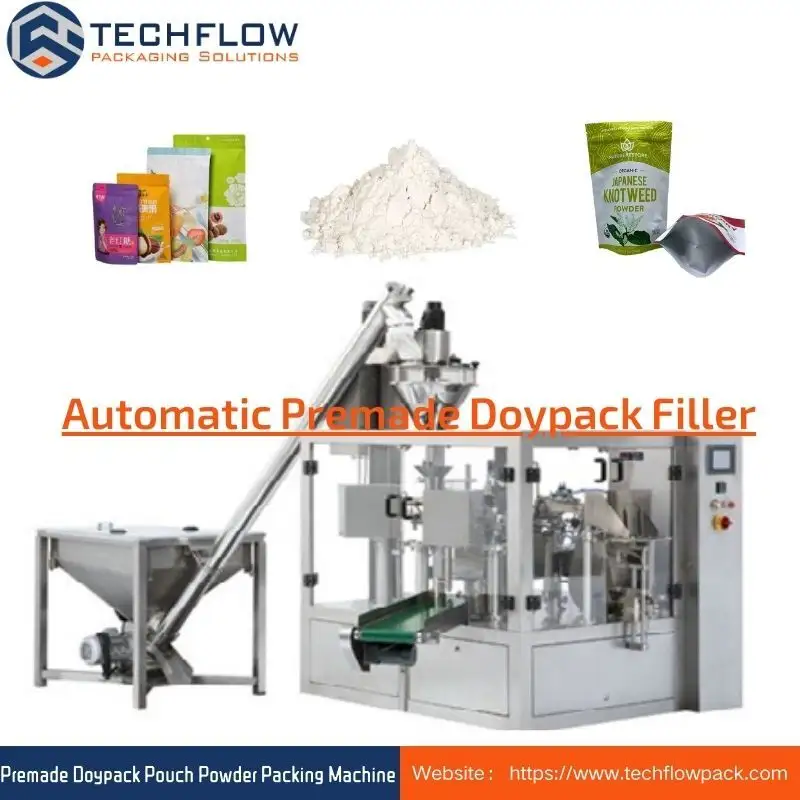

Product details of the powder pouch packing machine

Product Introduction

The design of Techflow Pack powder pouch packing machine is performed by a professional design team who are specialized in designing for a long time. This product complies with industrial quality standards. 上海利湃机械设备有限公司 has a higher product development capacity.

Product Description

Standing Bag Powder Packing Machine also called Standing bag powder filler or Stand-up Pouch powder Packer, is mainly used for powdery or fine granule products auto forming filling sealing by the premade bags. The working method is the screw conveyor linked to the standing bag packaging machine to get powdery materials auto infeeding and conveying into Auger Filler's hopper, with screw running to auto dosing the product into pouch for auto forming filling and sealing. And the packing speed could be adjustable according to the production capacity from 10-50bags per minute.

Applications

Automatted Premade Standing Bag Powder Packing Machine is the most common dosing equipment in the powder metering and powder packaging industry. It's suitable for filling and dosing a variety of powders or fine particles such as flour, coffee powder, milk powder, tapioca flour, seasoning powder, chemical powder and other materials into preformed standing bags or gusset bags or Doypack bags with auto forming and sealing. It's widely used in food, condiments, seasoning,coffee, beverage, pharmaceutical and other industries.

Technical Features 01

Use PLC Servo System and pneumatic control system and super touch screen to compose the drive control center which maximize the whole machine's control precision,reliability and intelligentized level.

Technical Features 02

The machine has the device with avoiding sealing empty bag and controls the non-sealing empty bag and don't waste the packaging bags.

Technical Features 03

Equipped with safety protection, comply with firm's safety management requirements.

Technical Features 04

Touch screen can store the technical parameters of various kinds of products ,it is unnecessary to reset while products changing.

Technical Parameters

|

Machine Model |

TFP-SP300 |

|

Metering method |

Screw quantitative |

|

Bag's application size |

(L)100-350mm, (W)80-230mm |

|

Production capacity |

Max 50pcs/min |

|

Filling volume |

100-5000ml(by screw changover) |

|

Gas pressure |

6-8 kg/cm2 0.3m3/min |

|

Power supply |

220/380V 50-60Hz, 3.5Kw |

|

Machine dimension |

2850x1500x175mm |

|

Machine weight |

800Kg |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

INOVANCE |

|

2 |

HMI |

INOVANCE |

|

3 |

Photo sensor |

SICK |

|

4 |

Servo motor |

INOVANCE/Delta |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

Airtac |

|

7 |

Main structure |

S.S304 |

Company Advantage

• With a focus on customers, Techflow Pack is committed to providing attentive service. According to the actual needs of customers, we could develop and produce high-quality machinery. We provide efficient and professional custom services.

• Based on the reinforcement of team building, our company created an excellent team with cohesion, creativity and execution.

• Techflow Pack's Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line are deeply trusted by customers. They occupy a large market share in China and are exported to Europe, America, Southeast Asia, and other countries and regions.

• Techflow Pack's Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line is available in multiple types and specifications. The quality is reliable, the price is reasonable, and the use is practical.

• Good location advantages and developed transportation and infrastructure are conducive to long-term development.

Welcome to Techflow Pack. Please leave your contact information and you will be provided with high-quality Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line at preferential prices.

No.99#Shenmei Road, Pudong District, Shanghai,China