Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Packaging Machinery Manufacturers Uppliers

product description

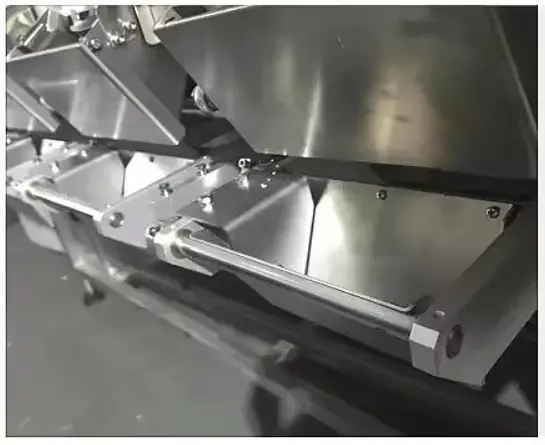

The automatic wafer sticks sorter counting machine consists of a main raw material storage bin, an equal-grid climbing belt conveyor, an integrated hopper, a photoelectric counting system, and a terminal output belt conveyor.Bulk sticks are transported from the raw material storage bin to the photoelectric counting system by the equal-grid climbing belt for counting. The quantitatively counted products load into the integrated hopper, and then enter the horizontal flow wrap packaging machine or cartoning machine station via the terminal belt conveyor.

Applications

Automatic Wafer Sorter Counting Machine is suitable for various stick shape products which need to count and pack such as breadstick, grissini, biscuit stick, chocolate dip cup, wafer roll, and ham sausage, crab stick, finger cookies, dipping stick cookies, coatedstick cookies, whole wheat bars, wafer rolls, and other stick shaped products etc.

Technical Features 01

The automatic wafer sorter counting system could finish automatically separating the tray, (biscuit stick, egg roll) counting the product and loading it into the tray automatically, sorting and packing function. No one touches the food in the whole packing process to reduce the

secondary pollution and meet the food hygiene requirement.

Technical Features 02

The process of sorting, conveying , feeding and packaging are fully automated, without manual operation.Customer can not only dump products on feeding belt by manual, but also connect with the production line Work in coordination, Speed change, automatic stop/start in case of material absence/supply and other intelligent control.

Technical Features 03

The automatic sticks sorter counting system realizing intelligently control the whole machine through the touch screen and embedded PLC real-time interactive operation. It collocates the product menu function that’s easy and quick to adjust the product.

Technical Features 04

PLC and servo control,touch screen display, packaging process visualization. Work stable, simple and convenient operation.

High precise and high sensitive SICK electric eye-tracking system to control accurately.

Technical Parameters

|

Model |

TFP-ZT300 |

|

Counting format |

Optoelectronic+ equal-grid belts |

|

Production capacity |

Max 120packs/min |

| Main belt width |

100/200 mm |

|

Power supply |

220V, 3Kw(customized) |

|

Machine dimension |

6000x1750x1300mm |

|

Machine weight |

1000Kg |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

Schneider/SIEMENS |

|

2 |

HMI |

Schneider/SIEMENS |

|

3 |

Photo sensor |

SICK |

|

4 |

Main Drive |

SEW |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

SMC/FESTO |

|

7 |

Frequency converters |

Schneider/Danfoss |

|

8 |

Main structure |

Stainless steel and Aviation aluminum |

Company Advantages

· The packaging machinery manufacturers designed by Techflow Pack professional designers are very competitive in this industry.

· The product has usability and long service life.

· 上海利湃机械设备有限公司 has a good operation system of production and quality control.

Company Features

· 上海利湃机械设备有限公司 remains committed to the manufacture of packaging machinery manufacturers for many years.

· 上海利湃机械设备有限公司 has deep technical strength and advanced equipment for packaging machinery manufacturers.

· Customer satisfaction has always been our main philosophy. As we continue to break through our business to achieve higher goals, we look forward to working with you. Contact us!

Application of the Product

Techflow Pack's packaging machinery manufacturers can meet the different needs of customers.

Techflow Pack is dedicated to solving your problems and providing you with one-stop and comprehensive solutions.

No.99#Shenmei Road, Pudong District, Shanghai,China