Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Packaging Machine Supplier Vendor

Product details of the packaging machine supplier

Quick Overview

packaging machine supplier is manufactured based on good raw materials. It enjoys a good reputation in the market for the following advantages: stable performance, high-degree of automation, high running speed, and long service life. 上海利湃机械设备有限公司 uses environmentally-recyclable materials as much as possible for packaging machine supplier. It has passed comprehensive performance tests before leaving the factory to ensure product quality. packaging machine supplier is widely used in the food industry, including the production, processing, and packaging of all types of food. 上海利湃机械设备有限公司 can ensure the fastest and most accurate delivery date for packaging machine supplier.

Product Information

Our packaging machine supplier has the following differentiated advantages compared to similar products.

product description

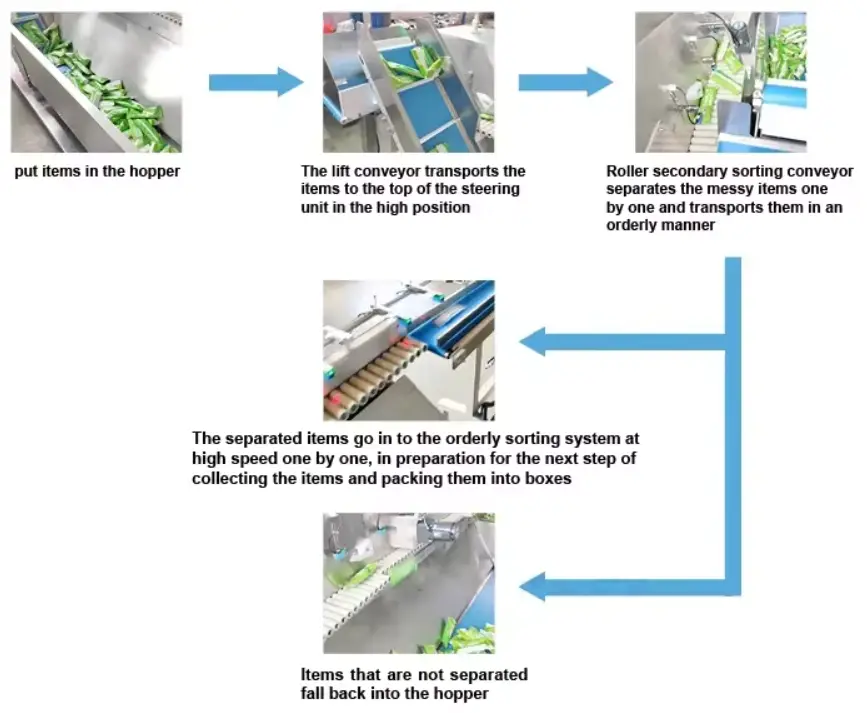

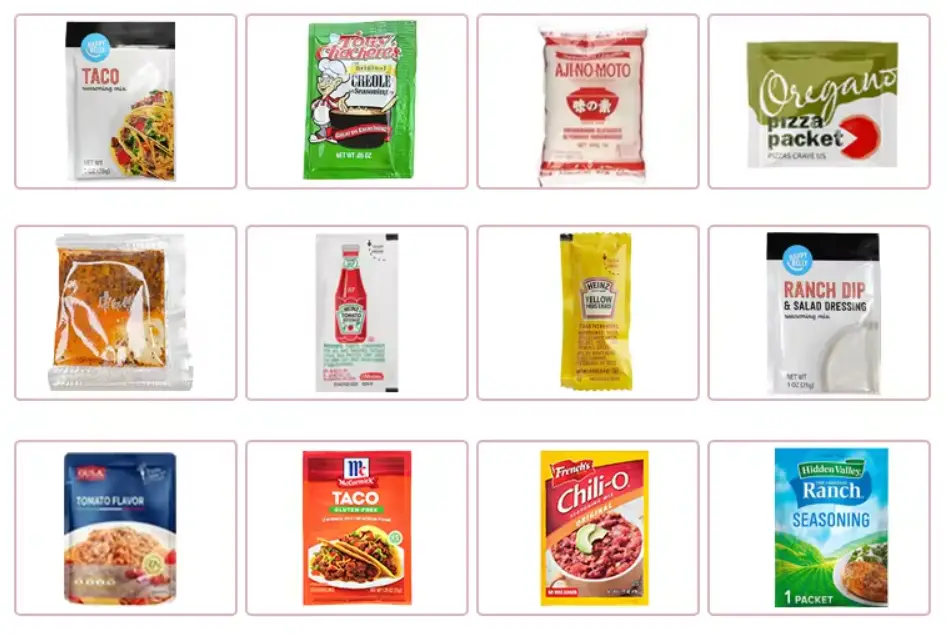

The automatic Seasoning Sachet Sorting Machine is mainly used for sesoning sachets orderly sorting and feeding. It can be used alone in production or connected with automatic cartoning machine or case packer machine to complete the whole sorting process of irregular stacked sachets from centralization to dispersion to sequential placement.

It can be seamlessly connected to the high-speed bagging production line and transport the ordered sachets to the cartoning machine station according to the predetermined quantity or grouping requirements, achieving a high degree of automation in bagging and boxing, improving the efficiency of subsequent packaging production and saving more. labor force.

Applications

Automatic Sachet Sorting Machine is generally applicable for Seasoning, beverage, dairy, snack food, daily chemical and other industries of granular sachets, powder sachets, and other small sticks of orderly sorting and feeding.

Technical Features 01

Food degree material designing with integrated large-capacity storage silo, can load large quantity products at one time and it's very easy to add products during the production then save more labors.

Technical Features 02

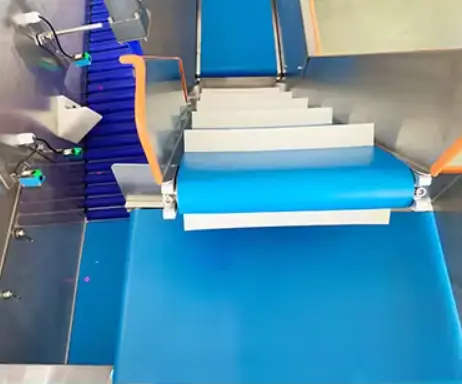

The bottom of the silo is equipped with belt conveyor, which is convenient for feeding and avoiding materials residue at the same time. Products are lifted at a constant speed to avoid execessive stacking of products.

Technical Features 03

Separate conveying roller is driven by multiple servo motors, speed adjustment by photoelectric sensor feedback signal, precise control, fast sachets management.

Technical Features 04

Customized brush sweeping device can gently remove products in the wrong direction and drop them into the silo to prepare re-sorting. Fully automatic arrangement by servo control method, multi-servo system to achieve material rules, orderly stacking, stable and controllable process.

Technical Parameters

|

Model |

TFP-SSM300 |

| Sachet size application |

L<180mm; W<120mm |

|

Machine Noise |

<80dB |

|

Production capacity |

Max 300packs/min |

|

Gas consumption |

100L/min |

|

Gas pressure |

0.5-08Mpa |

|

Power supply |

AC 380V, 3P 50Hz, 5.5Kw |

|

Machine dimension |

2250x950x1600mm |

|

Machine weight |

700Kg |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

INOVANCE/SIEMENS |

|

2 |

HMI |

INOVANCE/SIEMENS |

|

3 |

Photo sensor |

SICK |

|

4 |

Servo control |

INOVANCE |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

SMC/FESTO |

|

7 |

Main structure |

Stainless steel and Aviation aluminum |

Company Information

上海利湃机械设备有限公司, currently located in runs the main business of Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line. After years of unremitting efforts, Techflow Pack independently created Techflow Pack. And we have developed and manufactured multi series of machinery and supporting equipment. Our company has established a professional customer service team dedicated to providing assistance for consumers. Our company carries out standard production based on the advanced production equipment and a full set of quality inspection equipment. With the guarantee of reliable product quality, sufficient supply and efficient delivery, we could provide customers with quality custom services.

Dear customer, if you have any comments or suggestions on Techflow Pack's Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line, please leave your contact information. We will get further contact with you as soon as possible.

No.99#Shenmei Road, Pudong District, Shanghai,China