Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Custom Packaging Machine Supplier Cost Manufacturer | Techflow Pack

Product details of the packaging machine supplier

Product Information

The design and production of Techflow Pack packaging machine supplier are supported by a team of dedicated and skilled professionals. Our strict quality management system maintains the excellent performance and quality of our products. While providing users with cost-effective products, 上海利湃机械设备有限公司 is more focused on providing users with wholehearted services

product description

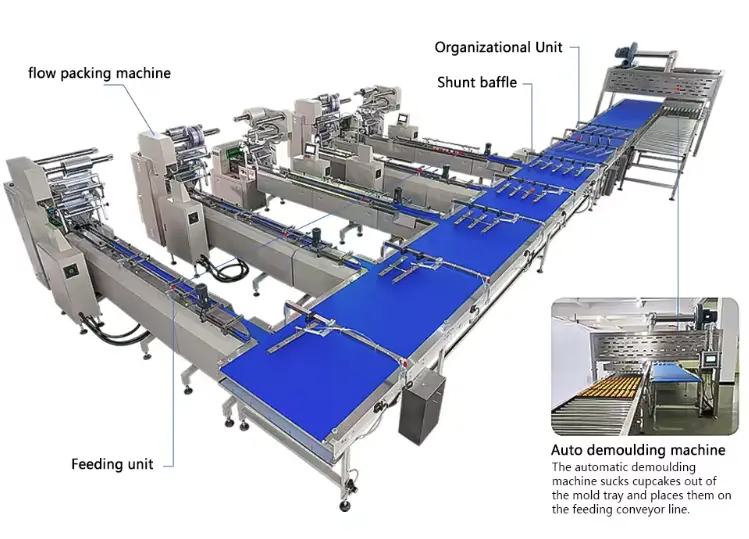

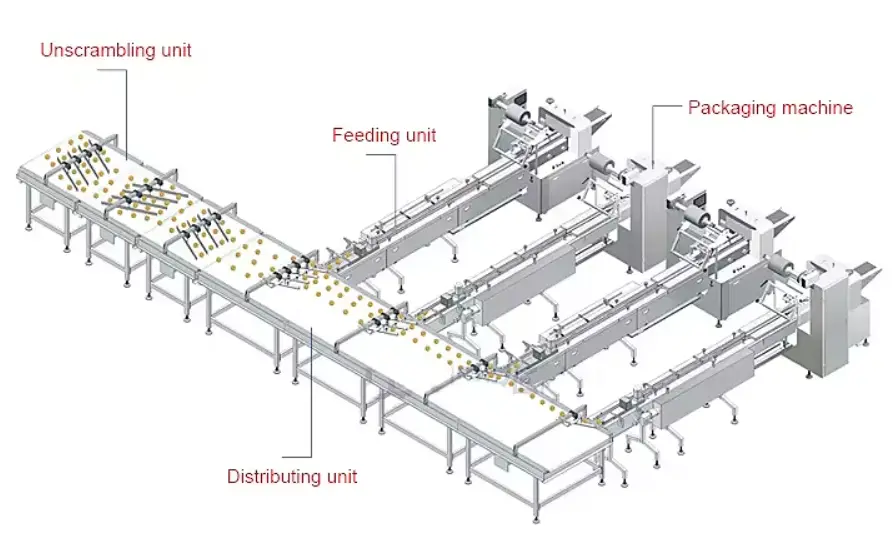

Automatic Candy Sorter Feeding Machine uses multi-stage Industry food-grade belt conveyor adding with SICK photoelectric tracking and set up the corresponding multi-lane dividing mechanisms based on the packaging format and outlet requirements of the subsequent packaging then feed the rows of candy products to the feed end of the packaging machine in an orderly manner. This Candy Sorter Feeding Machine is usually inserted in the middle of the Candy production line with the upstream connected to the candy making machine and the downstream connected to the candy Flow Wrap packaging machine or cartoner machine.

Applications

Automatic Candy Sorter Feeding Machine is mainly used for Candy, Cake, Chocolate snack food and other products of automatic grouping, arraying, sorting and feecding to achieve the purpose of secondary packaging preparation.

Technical Features 01

Using multiple sections of food-grade industrial conveyor lines with speed differences, supplemented by photoelectric tracking and visual recognition, the grouping and sorting are more efficient and accurate.

Technical Features 02

Set up a multi-column lane separation mechanism according to production capacity requirements, so that the products can travel in the established guidance direction after grouping to prepare for subsequent packaging.

Technical Features 03

lt adopts multi-level frequencyconversion speed regulation and servo drive control, which issimple to operate, stable in operation, high in control precision and low in energy consumption.

Technical Features 04

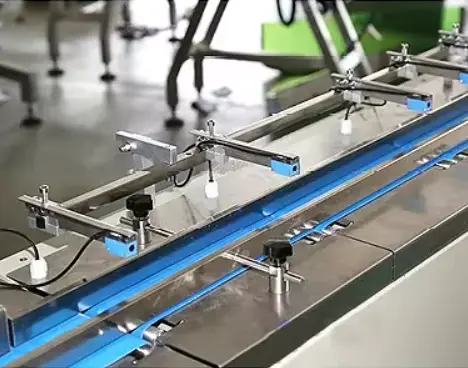

Using stainless steel and aluminum alloy structure, humanized design, installation, export-specific aviation wiring connector,disassembly and maintenance are simple and fast.

Technical Parameters

|

Model |

TFP-SC300 |

|

Arraying format |

Electric+Pneumatic |

|

Main conveyor width |

600/800/1000/1200mm |

|

Production capacity |

Max300pcs/min |

|

Gas consumption |

50L/min |

|

Gas pressure |

0.6-08Mpa |

|

Power supply |

AC 380V, 3P 50Hz,3.5Kw |

|

Machine dimension |

9000x950x1600mm |

|

Machine weight |

700Kg |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

Schneider/SIEMENS |

|

2 |

HMI |

Schneider/SIEMENS |

|

3 |

Photo sensor |

SICK |

|

4 |

Main Drive |

SEW |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

SMC/FESTO |

|

7 |

Frequency converters |

Schneider/Danfoss |

|

8 |

Main structure |

Stainless steel and Aviation aluminum |

Company Advantage

• Techflow Pack puts customers first and strives to provide quality and considerate services for customers.

• Founded in Techflow Pack has been focusing on the R&D and manufacture of machinery for many years. We continue to provide high-quality machinery in the future.

• Techflow Pack's marketing network covers all over the world.

• Techflow Pack's Auger Filler,Pouch Case Packer,Case Packer/Carton Packaging Machine,Case Erector/Carton Erector,Packing Line are reasonably designed. They are stable in performance and easy in operation. They are quality-reliable and use-durable.

• With a focus on customers, Techflow Pack can develop and produce quality machinery products and provide efficient and professional custom services, according to customers' actual needs.

Techflow Pack is always here. If you have any questions about the products we display, feel free to contact us at any time!

No.99#Shenmei Road, Pudong District, Shanghai,China