Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Bulk Buy Depalletizer Machine Price

Company Advantages

· The advanced production methods, along with the constant investment in research and development, ensures Techflow Pack depalletizer machine is finely and efficiently manufactured.

· Our quality testing department ensures that the product is of the quality that meets with the industry standards.

· The product is appropriate for various applications and is more widely used by people from various fields.

Product Description

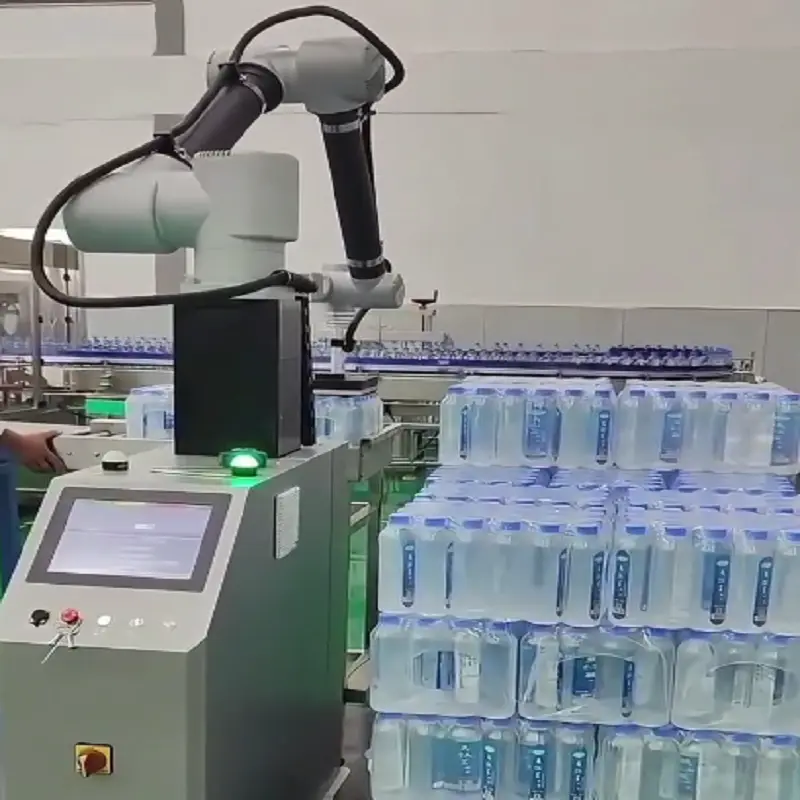

Collaborative robots, also known as cobots, are designed to work alongside human operators to enhance efficiency and productivity in manufacturing processes. Our Collaborative Robots Palletizer is specifically designed for automating the palletizing process, ensuring precision and speed in stacking products on pallets. Collaborative Robots Palletizer comes with several key features that set it apart from traditional palletizing machines. Firstly, it is designed to work alongside human operators in a shared workspace, ensuring safety and flexibility in your production line. The robot is equipped with advanced sensors and technology to detect and avoid obstacles, making it easy to integrate into your existing operations。Furthermore, our palletizer offers high-speed and precision stacking, ensuring consistent and reliable palletizing of your products. It can handle a wide range of items, from boxes to bags to containers, making it a versatile solution for various industries.

Product Specifications

| Max stacking height | Lifting maximum stackable height 2300mm (with pallet) |

| Pallet Max size | 1200mm×1200mm |

| Application sizes | L(260-500)mm*W(200-450)mm*H(150-400)mm |

| Max load | 25kg |

| Max working radius | 1600mm |

| Max speed | Stacks up to 8-11boxes per minute |

| Safety functions Optional | safety light grids, safety fences, safety sensing carpets |

| IP rating | IP54 for the arm, IP32 for the gripper and all other accessories. |

| HMI | Supports multiple safety inputs and outputs, including emergency stop, safety guard, administrator mode, and factory setup mode. |

| Safety function | Emergency stop function, reserved external safety interface (can be controlled through the I/O interface) |

| Indicator status | When powering up, the indicator light is green; when powering down, the indicator light is off. |

| Body material | Aluminum alloy, carbon brazed |

Product Application

The applications of our Collaborative Robots Palletizer are vast and include industries such as manufacturing, logistics, food and beverage, pharmaceuticals, and more. Whether you need to palletize boxes, bags, containers, or any other type of product, our palletizer can handle it all with precision and speed.

Products Advantages

Collaborative Robots Palletizer, a cutting-edge solution for automating the palletizing process in your facility. Our Collaborative Robots Palletizer offers a range of benefits that can significantly improve productivity and efficiency

WHY CHOOSE US?

Product Characteristics

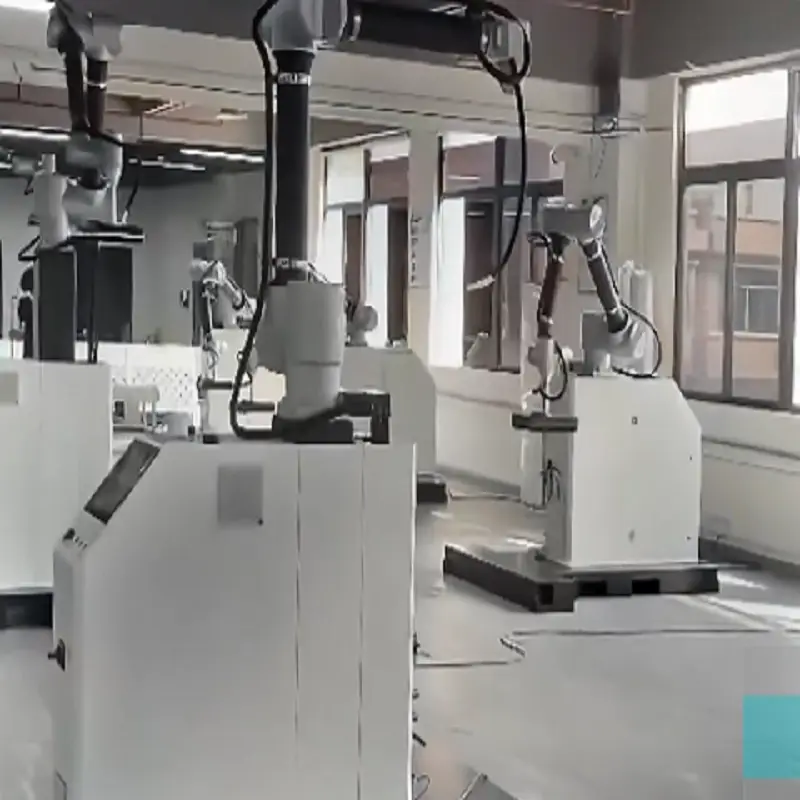

Our latest innovation in packaging technology - the Collaborative Robots Palletizer. This cutting-edge solution is designed to streamline the packaging process, increase efficiency, and improve overall productivity in your warehouse.

Product Details

Collaborative Robots Palletizer is designed to streamline the palletizing process in your warehouse or manufacturing facility. With advanced technology and intuitive programming, these robots can work alongside your existing workforce to efficiently stack, organize, and transport products onto pallets.

Video List

Demonstration of Collaborative Robots palletizers in different fields of application

Company Features

· Techflow Pack has made an outstanding achievement in depalletizer machine industry.

· The factory has a comprehensive supply chain management system. This system effectively and efficiently manages the supply chain from material suppliers to the company, including such managerial factors as people, data recording, and equipment.

· Our company is striving for green manufacturing. Our manufacturing systems maximize the use of raw materials and ensure the efficient use of natural resources to reduce our environmental footprint and customers'.

Product Comparison

Our depalletizer machine has a certain share in the market because of the following characteristics.

No.99#Shenmei Road, Pudong District, Shanghai,China