Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Automatic high speed cluster packer for 330ml-500ml Beer Cans Cardboard Packing

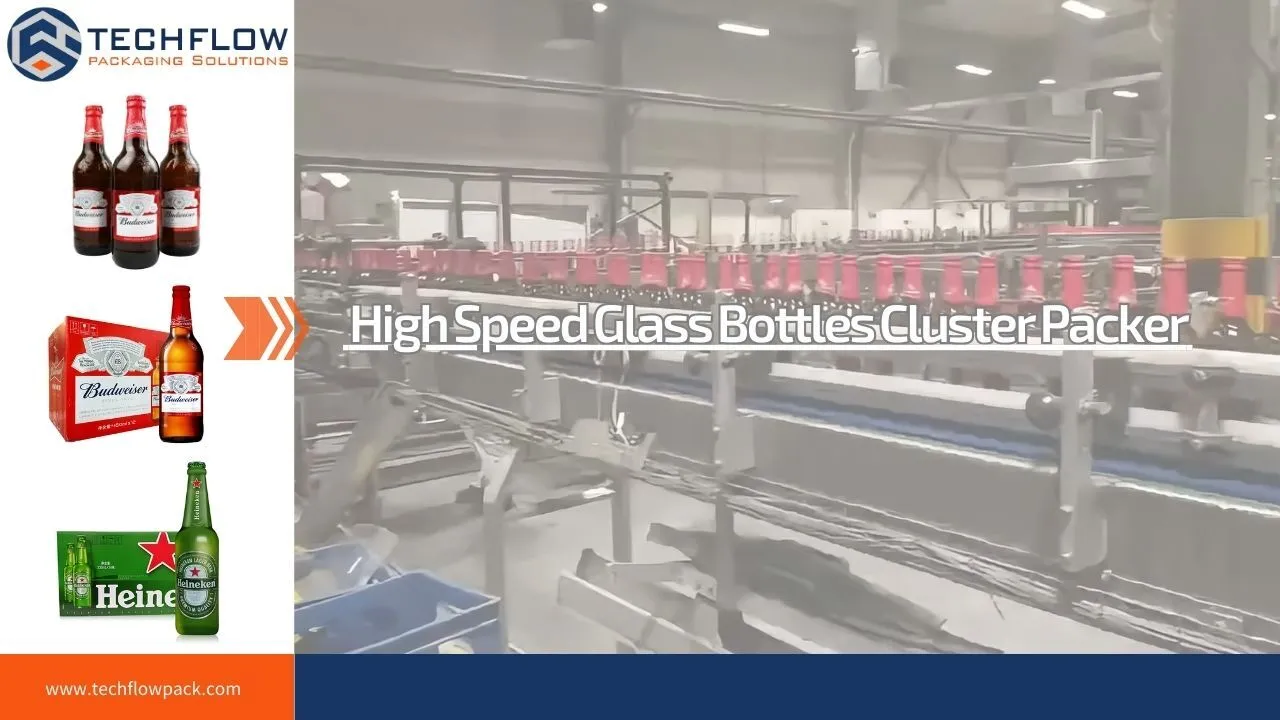

The Cluster Packaging Machine also called Cluster Packer or Cluster Machine, is a high-speed packaging solution realizing multipack by cardboard or paperboard glued in the upper part through the use of robotized stations.

Machine model: TFP-CPM-180

Packing format: 2x2; 2x3; 2x4; 3x4

Machine capacity: Max180 packs/min

Indicative price: $180,000-280,000

Applications: Bottles/Cans/Cups

Configuration: Siemens+Sew+Nordson+Schneider

product description

The Cluster Packaging Machine also called Cluster Packer or Cluster Machine, is a high-speed packaging solution realizing multipack by cardboard or paperboard glued in the upper part through the use of robotized stations.

The cardboard blanks are taken from the warehouse and placed under the product to be wrapped, and then folded and closed. The cluster packer is mainly used for beverage&Dairy high speed production line cups/bottles/cans/ cardboard packaging.

Applications

Cluster packaging machine is mainly used for beer, beverage, dairy, snack food, daily chemical and other industries of metal cans, glass bottles, plastic bottles (cups) and other products of cardboard collective packaging to achieve the purpose of commodity promotion.

Technical Features 01

Three sets of suction cups are used to suck the cardboard separately and position it directly with the grouping module, and the positioning accuracy is stable and does not cause the cardboard and bottle to be misaligned.

The adaptability to packaging materials is wide, and the customer verification test can be suitable for packaging materials of different manufacturers.Equipped with a suction alarm such as less bottles and other abnormal situations can be automatically stopped and alarm shutdown.

Technical Features 02

The chain is installed with a corresponding clamping pin and positioning pusher corresponding to the bottle type packaging material, when the product runs to this area, the card foot will be inserted into the hole corresponding to the cardboard to achieve positioning, and the positioning push block will ensure the position of the bottle and the jam paper, so as to achieve the accurate positioning of the cardboard and the bottle.

The mold is designed according to the shape of the bottle, which is consistent with the shape of the bottle, and the bottle positioning accuracy is high and the paper positioning is stable, which will not cause the phenomenon of jamming the bottle during operation, and will not top the paper misalignment when the cardboard hole is matched with the bottle.

Technical Features 03

Faster speed, high stability, up to 180 packs per minute (varies depending on the product and packaging format.Safety at work guardings consisting of fixed panels in stainless steel sheet in the lower side and openable hatches in tubular, with stainless steel net, in the upper side. These latter, that can be moved longitudinally, are complete with safety microswitch.

Technical Features 04

Equipped with NORDSON high-speed applicator. The spray gas pressure is controlled by analog quantity, and the corresponding air pressure is controlled according to the different speeds of the equipment, which ensures the uniform stability of the spray glue, equipped with product detection photoelectric, and fault alarm signal.

Technical Parameters

|

Model |

TFP-CPM-180 |

|

Container arraying format |

1x2;2x2;2x3;2x4; |

|

Infeeding height |

900mm |

|

Production capacity |

Max 180packs/min |

|

Gas consumption |

0.3L/min |

|

Gas pressure |

0.6-08Mpa |

|

Power supply |

AC 380V, 3P 50Hz, 15Kw |

|

Machine dimension |

5300x1950x2000mm |

|

Machine weight |

4000Kg |

Basic Configuration

|

No |

Items |

Brand |

|

1 |

PLC |

Schneider/SIEMENS |

|

2 |

HMI |

Schneider/SIEMENS |

|

3 |

Photo sensor |

SICK |

|

4 |

Main Drive |

SEW |

|

5 |

Electronic parts |

Schneider |

|

6 |

Pneumatic parts |

SMC/FESTO |

|

7 |

Frequency converters |

Schneider/Danfoss |

|

8 |

Main structure |

Stainless steel and Aviation aluminum |

No.99#Shenmei Road, Pudong District, Shanghai,China