Techflow Pack has been a professional automatic packaging machine manufacturer since 2006.

Revolutionizing Filling Processes: Unveiling The Auger Filling Machine

Welcome to our latest article, where we delve into the groundbreaking world of filling processes and unveil the revolutionary Auger Filling Machine. Are you searching for a game-changing solution that will transform your filling operations? Look no further! In this informative piece, we explore the incredible features and advantages of the Auger Filling Machine, designed to revolutionize the way you fill your products. Whether you are a business owner, manufacturer, or simply curious about the latest innovations in the industry, join us as we uncover the immense potential of this cutting-edge technology. Get ready to be fascinated by the possibilities and take a deep dive into the future of filling processes with the Auger Filling Machine!

The Evolution of Filling Processes: A Brief Overview

In the ever-evolving world of manufacturing, the efficiency and accuracy of filling processes play a crucial role. Over the years, filling machines have undergone a significant transformation, with the advent of advanced technologies. This article aims to provide a comprehensive overview of the revolutionary auger filling machine, a game-changer in the industry, and its profound impact on filling processes. Proudly developed by Techflow Pack, a leading innovator in packaging solutions, this state-of-the-art machine has redefined the way products are filled with precision and speed.

1. The Auger Filling Machine:

The auger filling machine is a highly advanced and automated instrument designed to streamline the filling process across various industries. It boasts a unique mechanism, which utilizes a rotating auger screw to accurately dispense powdered, granulated, or free-flowing products into containers. The result? An efficient, consistent, and speedy filling process that minimizes wastage and maximizes productivity.

2. Unparalleled Precision:

One of the key features that sets the auger filling machine apart from conventional filling methods is its unparalleled precision. Equipped with advanced sensors and computerized controls, the machine ensures that each container receives the exact quantity of product required, down to the smallest increments. This level of accuracy eliminates human error and guarantees consistent quality, ultimately boosting customer satisfaction and reducing product recalls.

3. Versatility and Adaptability:

Techflow Pack's auger filling machine is engineered to cater to a wide range of industries and products. Whether it's fillings for food and beverages, cosmetics, pharmaceuticals, or chemicals, this versatile machine can handle a diverse array of materials effortlessly. Moreover, the machine can be easily adjusted to accommodate a variety of container sizes and shapes, making it an ideal choice for businesses with multiple product lines or those looking to expand their offerings.

4. Flexibility and Control:

With the auger filling machine, manufacturers now have greater control and flexibility over their filling processes. The machine allows for precise adjustment of fill weights and speeds, ensuring that specific product requirements are met. This level of customization significantly reduces product waste, thereby increasing cost-effectiveness and contributing to a more sustainable production cycle.

5. Time and Cost Efficiency:

Techflow Pack's auger filling machine is a game-changer in terms of time and cost efficiency. It eliminates the need for manual filling methods, saving substantial labor costs and reducing the risk of workplace accidents. Additionally, the machine's high-speed filling capabilities enable manufacturers to meet increased production demands without sacrificing quality. The combination of speed, accuracy, and adaptability allows businesses to maximize their output, leading to higher profitability and a competitive edge in the market.

6. Auger Filling Machine: A Wise Investment:

Investing in a Techflow Pack auger filling machine proves to be a wise business decision for manufacturers looking to revolutionize their filling processes. Not only does it enhance productivity and efficiency, but it also ensures product consistency, reduces wastage, and improves customer satisfaction. By aligning with Techflow Pack's commitment to innovation and precision packaging solutions, businesses can stay ahead of the competition and meet the evolving demands of their industry.

In conclusion, the auger filling machine, developed by Techflow Pack, has revolutionized filling processes across various industries. Its unrivaled precision, versatility, and time and cost efficiency make it an invaluable asset for businesses looking to enhance their productivity and optimize their operations. With Techflow Pack's auger filling machine, manufacturers can empower themselves with complete control over their product filling, ultimately leading to improved profitability and customer satisfaction.

Introducing the Auger Filling Machine: A Breakthrough Innovation

In the fast-paced world of manufacturing and packaging, companies are constantly on the lookout for innovative solutions that can streamline their processes and improve efficiency. One such breakthrough in the industry is the Auger Filling Machine, and Techflow Pack is proud to introduce this revolutionary device.

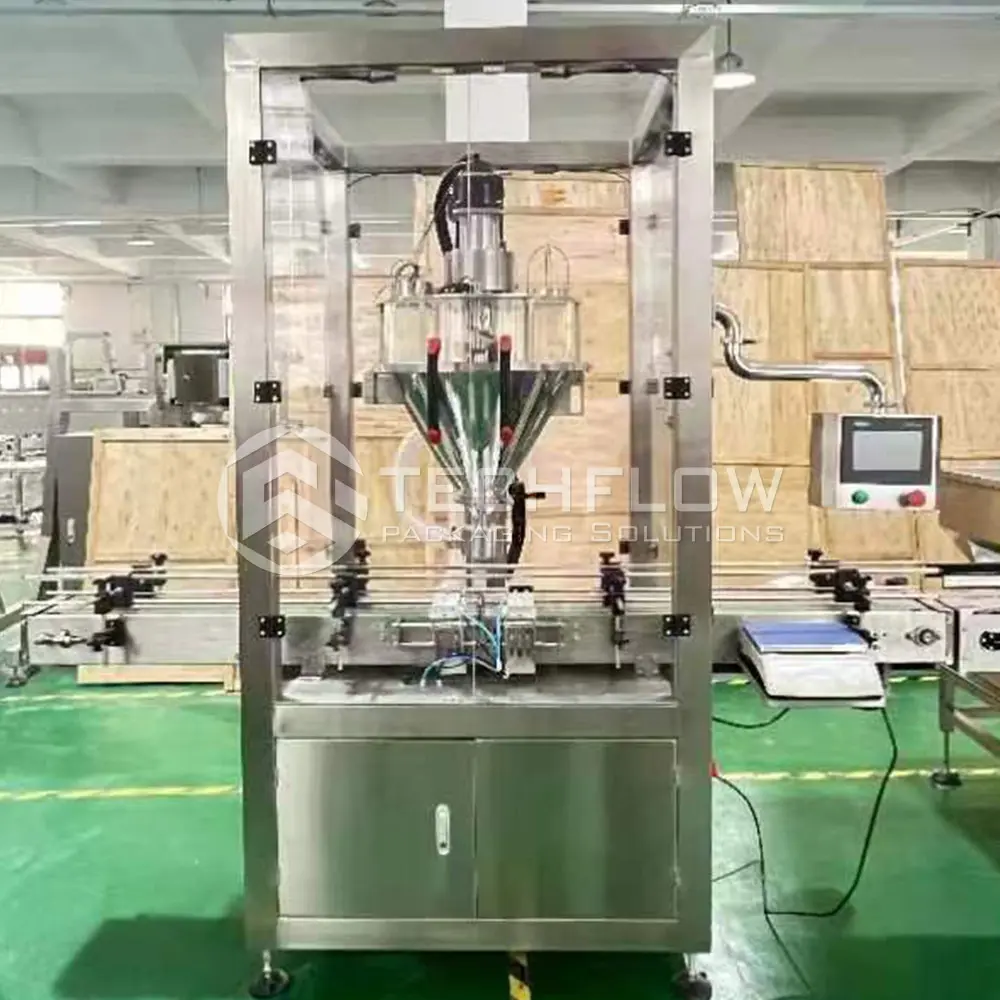

The Auger Filling Machine is a state-of-the-art equipment designed to precisely and efficiently fill containers with various dry or powdered substances. This cutting-edge technology is reshaping the way companies approach their filling processes, offering numerous benefits that were previously unimaginable.

Techflow Pack, the leading provider of packaging machinery, has developed the Auger Filling Machine to help businesses meet the increasing demand for accurate and consistent filling of products. With this groundbreaking device, Techflow Pack is setting a new standard in the industry, ensuring high-quality packaging and enhancing customer satisfaction.

One of the key advantages of the Auger Filling Machine is its unparalleled accuracy. Using advanced digital controls and sensors, the machine measures the exact quantity of the product to be dispensed, eliminating any guesswork or human error. This precise filling capability ensures that each container is filled to the desired weight, saving both time and resources.

Furthermore, the Auger Filling Machine offers remarkable versatility. With its adjustable settings, it can accommodate a wide range of products, including powders, spices, chemicals, and even pharmaceuticals. This flexibility allows manufacturers to use the machine for multiple applications, eliminating the need for separate filling equipment or manual labor.

Techflow Pack's Auger Filling Machine also boasts an impressive speed and efficiency. Equipped with a high-speed auger, the device can fill containers at a rapid pace, optimizing production rates and reducing downtime. Its automated functions further contribute to its efficiency, enabling operators to focus on other important tasks while the machine handles the filling process.

Customer satisfaction is a top priority for Techflow Pack, and the Auger Filling Machine plays a significant role in achieving this objective. The machine is engineered for easy operation and maintenance, ensuring that users can quickly adapt and maximize its capabilities. Additionally, its compact design and user-friendly interface make it an ideal solution for companies with limited space or staff.

In terms of safety, the Auger Filling Machine adheres to the highest industry standards. It is equipped with advanced safety features, such as emergency stop buttons and protective enclosures, to minimize the risk of accidents or injuries. This commitment to safety reinforces Techflow Pack's dedication to providing reliable and trustworthy equipment.

The advantages of the Auger Filling Machine extend beyond its technical capabilities. By implementing this innovative device, companies can reduce product wastage and improve cost-effectiveness. The machine's precise filling mechanism ensures that every product is utilized efficiently, minimizing the amount of excess material or spillage.

In conclusion, Techflow Pack's Auger Filling Machine is set to revolutionize the filling processes of various industries. This breakthrough innovation offers unmatched accuracy, versatility, speed, efficiency, and safety. With the Auger Filling Machine, manufacturing and packaging companies can streamline their operations, improve customer satisfaction, and enhance their competitive edge in the market. Techflow Pack continues to lead the industry with innovative solutions, and the Auger Filling Machine is a testament to the company's commitment to excellence.

Unveiling the Key Features and Advantages of Auger Filling Technology

In the fast-paced world of packaging and filling processes, Techflow Pack has revolutionized the industry with its innovative Auger Filling Machine. This article aims to delve into the key features and advantages of this cutting-edge technology that has transformed the way products are filled, ensuring precision, efficiency, and reliability.

Unveiling the Key Features of Auger Filling Technology:

The Auger Filling Machine, developed by Techflow Pack, integrates advanced technology to provide a superior filling solution for various industries. Here, we explore the key features that make this machine stand out.

1. Precision and Accuracy:

The Auger Filling Machine employs a precision-driven auger mechanism, which ensures accurate and consistent product filling. This technology enables precise measurement of fill weights, minimizing product wastage, and ensuring optimum efficiency.

2. Flexibility in Filling Applications:

Techflow Pack's Auger Filling Machine offers unrivaled versatility when it comes to filling various products. From powders, granules, and spices to pharmaceuticals and chemicals, this machine can handle a wide range of materials with ease. Its adjustable filling settings allow for efficient packaging of different product consistencies and densities.

3. Customizable Configuration:

One of the standout features of the Auger Filling Machine is its customizable configuration. Techflow Pack understands that each industry and product may have specific requirements. Therefore, the machine can be tailored to suit the unique needs of the client, ensuring maximum efficiency and productivity.

Advantages of Auger Filling Technology:

Incorporating the Auger Filling Machine into your production line brings numerous advantages for your business. Let's explore some of these advantages that set this technology apart from traditional filling processes.

1. Increased Efficiency:

By automating the filling process, the Auger Filling Machine drastically improves efficiency and productivity. With its high-speed operation and accurate measurements, it allows for faster production cycles, reducing downtime and increasing output.

2. Cost-effectiveness:

Auger filling technology offers cost-effective solutions for businesses. Its precise measurement capabilities minimize product wastage, leading to substantial cost savings in the long run. Additionally, the customizable configuration ensures that only the necessary components are included, avoiding unnecessary expenses.

3. Hygiene and Cleanliness:

Maintaining high levels of hygiene and cleanliness is crucial, particularly in industries such as food, pharmaceuticals, and cosmetics. The Auger Filling Machine's design incorporates easy-to-clean components that can be disassembled quickly, ensuring thorough cleaning between production runs. This feature promotes product integrity and compliance with regulatory standards.

4. Enhanced Product Shelf Life:

The precision and accuracy of the Auger Filling Machine contribute to better product quality and longer shelf life. By minimizing the exposure of products to air and moisture, it prevents spoilage and preserves the freshness and potency of goods over time.

Techflow Pack's Auger Filling Machine has emerged as a game-changer in the packaging and filling industry. Its superior features, including precision, versatility, and customizability, have revolutionized the way products are filled. With enhanced efficiency, cost-effectiveness, hygiene, and product shelf life, this technology is a worthy investment for businesses looking to stay ahead in a competitive market. Embrace the future of filling processes with Techflow Pack's Auger Filling Machine.

Streamlining Filling Processes: How the Auger Filling Machine Works

In today's fast-paced world, efficiency is key. Whether it's in manufacturing, packaging, or any other industry, businesses need to find innovative ways to streamline their processes and reduce downtime. One such game-changing technology that is revolutionizing the filling process is the auger filling machine. Developed and manufactured by Techflow Pack, this cutting-edge machine is set to transform the way products are packaged, ensuring accuracy, speed, and reliability.

Techflow Pack, a leading provider of packaging solutions, has designed the auger filling machine to cater to the growing demand for a more efficient filling process. With a focus on streamlining operations, this machine is optimized to handle various types of products, from powders and granules to liquids and semi-liquids. Its versatility makes it an ideal solution for a wide range of industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals.

The principle behind the auger filling machine lies in its auger mechanism. At its core, the machine features a rotating helical auger that is responsible for filling containers with precise amounts of product. The auger, driven by a powerful motor, works in tandem with a hopper, which holds the product prior to dispensing. As the auger rotates, it gradually moves the product from the hopper into the container, ensuring an accurate and controlled filling process.

One of the key advantages of the auger filling machine is its ability to handle a wide range of product consistencies. With interchangeable auger attachments, Techflow Pack's machine can accommodate both free-flowing and non-free-flowing products. This flexibility allows businesses to use a single machine for multiple products, eliminating the need for separate filling solutions and reducing costs.

Another noteworthy feature of the auger filling machine is its high-speed operation. Thanks to its precise control and efficient design, this machine can fill hundreds of containers per minute, significantly increasing productivity compared to traditional filling methods. This speed is achieved without compromising accuracy, as the machine can be programmed to dispense specific weights or volumes, ensuring consistent and uniform filling across all products.

Furthermore, the auger filling machine is equipped with advanced software and electronic controls, providing businesses with real-time monitoring and data logging capabilities. This enables operators to track and analyze the filling process, ensuring quality control and identifying any potential bottlenecks or issues. The machine can also be integrated with existing production lines, allowing for seamless automation and workflow optimization.

Techflow Pack's auger filling machine not only optimizes the filling process but also prioritizes safety and hygiene. The machine is constructed with high-quality, food-grade materials, ensuring compliance with industry standards and regulations. Additionally, it features user-friendly interfaces and safety features, such as emergency stop buttons and protective enclosures, to protect operators and prevent accidents.

In conclusion, the auger filling machine developed by Techflow Pack is set to revolutionize the filling process across various industries. With its versatility, speed, accuracy, and safety features, it offers businesses a cost-effective and efficient solution for their packaging needs. By streamlining filling processes and reducing downtime, the auger filling machine allows companies to enhance their productivity and meet growing consumer demands. Whether it's powders, granules, liquids, or semi-liquids, Techflow Pack's auger filling machine is the answer to optimizing filling operations and driving success in the modern-day competitive market.

Transforming Industries: The Implications and Benefits of Auger Filling

In today's rapidly evolving industrial landscape, the need for efficient and accurate filling processes has become paramount. Auger filling machines have emerged as a game-changer in this space, revolutionizing various industries with their superior capabilities. In this article, we explore the implications and benefits of auger filling and highlight how Techflow Pack's state-of-the-art auger filling machines are transforming industries worldwide.

Implication 1: Enhanced Efficiency and Accuracy

Auger filling machines employ a unique mechanism that ensures precise filling of a variety of products, ranging from powders, granules, and even viscous liquids. This technology eliminates common bottlenecks associated with manual filling, such as inconsistency, spillage, and wastage. Techflow Pack's auger filling machines employ advanced servo-driven systems, allowing for adjustable fill volumes with exceptional accuracy, reducing errors and material losses.

Implication 2: Flexible and Versatile Application

The versatility of auger filling machines is a testament to their transformative potential in multiple industries. Designed to accommodate different container sizes, shapes, and materials, these machines can be seamlessly integrated into existing production lines across various sectors. Techflow Pack's auger filling machines provide customized attachments and adaptations, enabling manufacturers to fill an extensive range of products, including food items, pharmaceuticals, chemicals, and cosmetics.

Implication 3: Improved Productivity and Cost Savings

Auger filling machines not only optimize production efficiency but also contribute to significant cost savings. By automating the filling process, companies reduce labor costs, minimize product waste, and enhance overall operational throughput. Techflow Pack's auger filling machines boast high-speed operation capabilities, enabling manufacturers to achieve higher output without compromising product quality. This increased productivity translates into better profit margins and a competitive advantage in the market.

Benefit 1: Accurate Fill Volume Control

With precision being a critical factor in the filling process, auger filling machines offer unparalleled accuracy. Techflow Pack's auger filling machines leverage cutting-edge technology, allowing manufacturers to set desired fill volumes precisely. This level of control minimizes product giveaway, maximizes yield, and ensures an optimal customer experience by consistently delivering the exact amount of product, generating customer loyalty and satisfaction.

Benefit 2: Ease of Operation and Maintenance

Techflow Pack's auger filling machines are engineered with user-friendliness in mind. The intuitive interfaces and advanced control systems facilitate seamless operation, reducing training time and operator errors. The machines are equipped with self-diagnostic and easy-to-access components, simplifying maintenance procedures and minimizing downtime. With Techflow Pack's commitment to exceptional customer service, clients can rely on prompt technical support and quick resolution of any concerns, ensuring uninterrupted production and peace of mind.

Benefit 3: Compliance with Industry Standards

Techflow Pack's auger filling machines comply with stringent industry standards and regulations, ensuring optimal product safety and conformity. Built with high-quality materials and subjected to rigorous testing, these machines are designed to meet global quality and hygiene requirements. From food-grade stainless steel construction to features like dust tight enclosures and clean-in-place (CIP) systems, Techflow Pack's auger filling machines guarantee the utmost sanitation, protecting both manufacturers and end-users.

Auger filling machines have ushered in a new era in the filling process, revolutionizing industries with their efficiency, accuracy, versatility, and cost-saving potential. Techflow Pack's auger filling machines exemplify these benefits, providing manufacturers with state-of-the-art solutions to optimize their operations while maintaining compliance with industry standards. With Techflow Pack's commitment to innovation, service excellence, and customized solutions, businesses can embark on a transformative journey toward operational excellence and heightened competitiveness in the market.

Conclusion

In conclusion, the unveiling of the Auger Filling Machine marks a revolutionary turning point in filling processes for various industries. With our 8 years of expertise in the sector, we have witnessed firsthand the challenges faced by companies when it comes to efficient and accurate filling. However, with the introduction of this innovative technology, these challenges have been overcome, paving the way for enhanced productivity and cost-effectiveness. As we continue to evolve as a company, we remain committed to providing our clients with state-of-the-art solutions that revolutionize their operations. With the Auger Filling Machine leading the way, the future of filling processes has never looked brighter. Join us on this exciting journey as we reshape the industry and set new benchmarks for excellence.

No.99#Shenmei Road, Pudong District, Shanghai,China